Aerobatic aircraft built for stunts are designed and constructed with specific modifications and considerations to enable them to perform a wide range of aerial maneuvers safely and effectively. Let’s explore the general overview of How the Aerobatic Aircrafts are build for stunts?

Design Phase:

The design phase of an aerobatic aircraft is a complex and challenging process. It involves carefully considering a wide range of factors, including the aircraft’s aerodynamics, performance, strength, and weight.

The first step in the design phase is to define the aircraft’s mission requirements. What type of aerobatic maneuvers will it be used for? What level of performance is required? How many people will it need to carry? Once the mission requirements are defined, the designers can begin to develop a preliminary design.

The preliminary design includes defining the aircraft’s overall configuration, such as its wingspan, length, and height. The designers will also select the appropriate engine and propeller. Once the preliminary design is complete, the designers will begin to conduct more detailed aerodynamic and structural analyses.

Aerobatic aircraft are subjected to high stresses during maneuvers such as rolls, loops, and spins. It is important to ensure that the aircraft is strong enough to withstand these stresses. The designers will use computer simulations and wind tunnel testing to analyze the aircraft’s aerodynamics and strength.

Once the aerodynamic and structural analyses are complete, the designers can begin to finalize the aircraft’s design. This includes detailing the design of the wings, fuselage, landing gear, and other components. The designers will also develop a detailed manufacturing plan.

The design phase of an aerobatic aircraft is a critical step in the development process. By carefully considering all of the relevant factors, the designers can create an aircraft that is safe, reliable, and high-performance.

Here are some of the key considerations in the design of an aerobatic aircraft:

- Aerodynamics: Aerobatic aircraft need to be able to perform a wide range of maneuvers, including rolls, loops, and spins. The aircraft’s aerodynamics must be carefully designed to ensure that it is stable and controllable throughout its entire flight envelope.

- Performance: Aerobatic aircraft need to be powerful and agile. The aircraft’s engine and propeller must be carefully selected to provide the required power and thrust. The aircraft’s wings and fuselage must also be designed to minimize drag and maximize performance.

- Strength: Aerobatic aircraft are subjected to high stresses during maneuvers. The aircraft’s structure must be strong enough to withstand these stresses. The aircraft’s materials and construction methods must be carefully selected to ensure that the aircraft is safe and reliable.

- Weight: Aerobatic aircraft need to be lightweight to maximize performance. The aircraft’s components must be designed to be as light as possible without sacrificing strength or reliability.

Structural Reinforcement:

Structural reinforcement of aerobatic aircraft is necessary to ensure that the aircraft can safely withstand the high stresses imposed during aerobatic maneuvers. Aerobatic aircraft are subjected to a wide range of loads, including positive and negative g-forces, high airspeeds, and rapid changes in direction. These loads can be significantly higher than those experienced by conventional aircraft.

There are a number of different ways to reinforce the structure of an aerobatic aircraft. Some common methods include:

- Using stronger materials: Stronger materials, such as high-strength aluminum alloys and carbon fiber composites, can be used to construct the aircraft’s structure. These materials can withstand higher loads without adding significant weight to the aircraft.

- Adding additional structural members: Additional structural members, such as gussets, braces, and spars, can be added to the aircraft’s structure to increase its strength. These members can help to distribute loads more evenly and prevent the structure from failing.

- Redesigning critical components: Critical components of the aircraft, such as the wings, fuselage, and landing gear, can be redesigned to increase their strength and durability. This may involve changing the shape of the components, using thicker materials, or adding additional structural features.

The specific structural reinforcement measures that are required will vary depending on the type of aerobatic aircraft and the maneuvers that it will be used for. For example, an aircraft that will be used for high-performance aerobatics, such as competitive aerobatic competitions, will require more extensive structural reinforcement than an aircraft that will only be used for basic aerobatic maneuvers.

It is important to note that structural reinforcement can add weight to the aircraft. This can reduce the aircraft’s performance and payload capacity. It is therefore important to carefully consider the trade-offs between structural strength and aircraft weight when designing an aerobatic aircraft.

Here are some examples of structural reinforcement measures that are commonly used in aerobatic aircraft:

- Wing spars: Wing spars are the main load-bearing members of the wings. They are typically made of high-strength aluminum alloys or carbon fiber composites. In aerobatic aircraft, wing spars are often reinforced with additional material or with additional structural members, such as gussets and braces.

- Fuselage: The fuselage is the main body of the aircraft. It is responsible for carrying the aircraft’s payload and supporting the wings and other components. In aerobatic aircraft, the fuselage is often reinforced with additional material or with additional structural members, such as bulkheads and stringers.

- Landing gear: The landing gear is responsible for supporting the aircraft on the ground and during takeoff and landing. In aerobatic aircraft, the landing gear is often reinforced with additional material or with additional structural members to withstand the high stresses imposed during aerobatic maneuvers.

Structural reinforcement is an important part of the design and construction of aerobatic aircraft. By carefully considering the loads that the aircraft will be subjected to and by using the appropriate structural reinforcement measures, designers can create an aircraft that is safe and reliable for aerobatic flying.

High-Power Engines:

High-power engines are an essential component of aerobatic aircraft. Aerobatic maneuvers require a lot of thrust, and high-power engines can provide the necessary thrust to perform these maneuvers safely and efficiently.

There are a number of different factors that need to be considered when designing an engine for an aerobatic aircraft. Some of the most important factors include:

- Power output: Aerobatic aircraft need engines that can produce a high amount of power. This power is needed to accelerate the aircraft quickly, climb to high altitudes, and perform aerobatic maneuvers.

- Weight: Aerobatic aircraft need engines that are lightweight. This is because the weight of the engine directly affects the aircraft’s performance.

- Reliability: Aerobatic engines need to be highly reliable. Aerobatic maneuvers can put a lot of stress on the engine, so it is important that the engine is able to withstand these stresses without failing.

- Fuel efficiency: Aerobatic aircraft need engines that are fuel-efficient. This is because aerobatic maneuvers can consume a lot of fuel.

Some common types of high-power engines that are used in aerobatic aircraft include:

- Reciprocating engines: Reciprocating engines are the most common type of engine used in aerobatic aircraft. They are relatively lightweight and produce a good amount of power. However, they can be less fuel-efficient than other types of engines.

- Turbine engines: Turbine engines are more powerful and fuel-efficient than reciprocating engines. However, they are also heavier and more expensive. Turbine engines are typically used in high-performance aerobatic aircraft, such as those used in competitive aerobatic competitions.

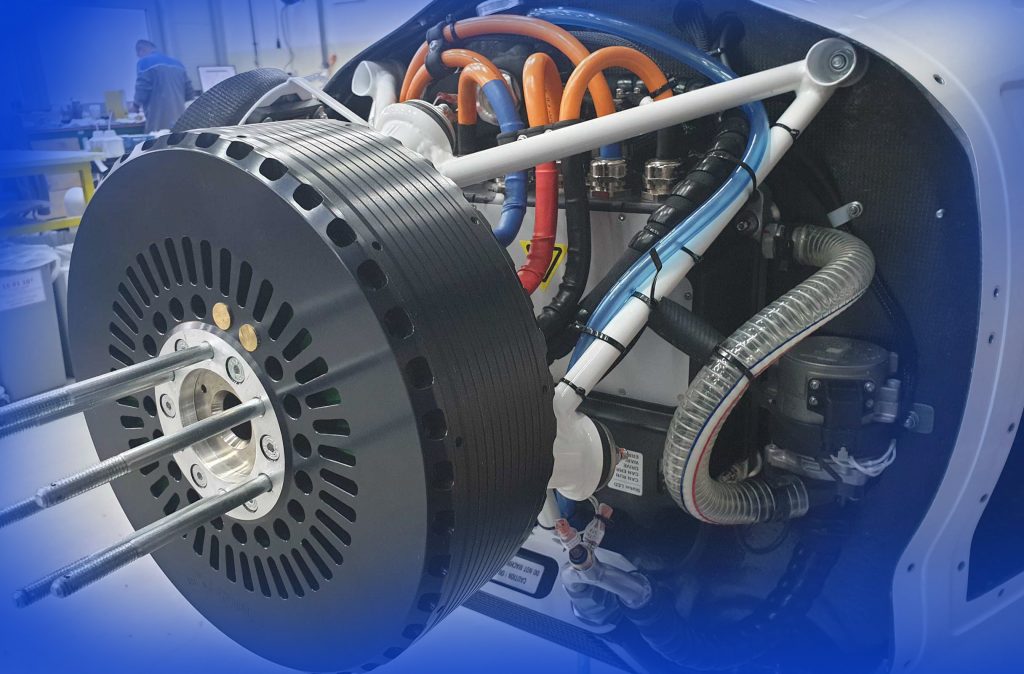

- Electric motors: Electric motors are becoming increasingly popular in aerobatic aircraft. They are lightweight and fuel-efficient. However, they are not as powerful as reciprocating or turbine engines. Electric motors are typically used in low-performance aerobatic aircraft, such as those used for training or recreational flying.

The specific type of high-power engine that is used in an aerobatic aircraft will depend on the type of aircraft and the maneuvers that it will be used for. For example, a high-performance aerobatic aircraft that is used for competitive aerobatic competitions will require a more powerful engine than a low-performance aerobatic aircraft that is used for training or recreational flying.

When designing an engine for an aerobatic aircraft, it is important to consider the needs of the pilot and the aircraft. The engine should be able to provide the necessary thrust to perform all of the desired aerobatic maneuvers, but it should also be lightweight, reliable, and fuel-efficient.

Performance Propellers:

Performance propellers are designed to maximize the performance of aerobatic aircraft. They are typically made of lightweight and durable materials, such as carbon fiber or aluminum. Performance propellers also have a number of other features that make them ideal for aerobatic flying, such as:

- High blade pitch: Performance propellers have a high blade pitch, which allows them to generate more thrust. This is essential for aerobatic aircraft, which need to be able to accelerate quickly and climb to high altitudes.

- Wide blade chord: Performance propellers have a wide blade chord, which gives them more surface area. This helps to increase lift and reduce drag, which improves the aircraft’s overall performance.

- Aerodynamic design: Performance propellers are aerodynamically designed to minimize drag and maximize efficiency. This is important for aerobatic aircraft, which need to conserve fuel during long flights and aerobatic maneuvers.

Some of the benefits of using performance propellers on aerobatic aircraft include:

- Increased thrust: Performance propellers can generate more thrust than standard propellers. This can improve the aircraft’s acceleration, climb rate, and top speed.

- Improved performance: Performance propellers can improve the aircraft’s overall performance, including its climb rate, cruise speed, and fuel efficiency.

- Reduced vibration: Performance propellers are typically better balanced than standard propellers, which can reduce vibration and improve the aircraft’s ride quality.

Some examples of performance propellers that are commonly used on aerobatic aircraft include:

- MT Propellers: MT Propellers is a leading manufacturer of performance propellers for aerobatic aircraft. Their propellers are known for their high quality, performance, and durability.

- Hartzell Propeller: Hartzell Propeller is another leading manufacturer of performance propellers for aerobatic aircraft. Their propellers are also known for their high quality, performance, and durability.

- Whirlwind Propellers: Whirlwind Propellers is a manufacturer of high-performance propellers for aerobatic and other aircraft. Their propellers are known for their innovative designs and excellent performance.

When choosing a performance propeller for an aerobatic aircraft, it is important to consider the type of aircraft and the maneuvers that it will be used for. For example, an aircraft that will be used for high-performance aerobatics, such as competitive aerobatic competitions, will require a more aggressive propeller than an aircraft that will only be used for basic aerobatic maneuvers.

It is also important to note that performance propellers can be more expensive than standard propellers. However, the increased performance and durability of performance propellers can make them worth the investment for aerobatic pilots.

Lightweight Materials:

Lightweight materials are essential for aerobatic aircraft. Aerobatic aircraft need to be lightweight to maximize performance and maneuverability. Lightweight materials also help to reduce the amount of fuel needed to fly the aircraft, which can extend the aircraft’s range and endurance.

A number of different lightweight materials are used in the construction of aerobatic aircraft, including:

- Aluminum alloys: Aluminum alloys are one of the most common lightweight materials used in aerobatic aircraft. They are strong, lightweight, and relatively inexpensive. Aluminum alloys are used in a variety of components on aerobatic aircraft, including the wings, fuselage, and landing gear.

- Carbon fiber composites: Carbon fiber composites are another common lightweight material used in aerobatic aircraft. They are even stronger than aluminum alloys and also very lightweight. Carbon fiber composites are used in a variety of components on aerobatic aircraft, including the wings, fuselage, and propeller blades.

- Titanium alloys: Titanium alloys are the strongest and lightest of the common lightweight materials used in aerobatic aircraft. However, they are also the most expensive. Titanium alloys are used in critical components on aerobatic aircraft, such as the landing gear and highly stressed areas of the wings and fuselage.

The specific lightweight materials that are used in an aerobatic aircraft will depend on the type of aircraft and the maneuvers that it will be used for. For example, a high-performance aerobatic aircraft that is used for competitive aerobatic competitions will require more lightweight materials than a low-performance aerobatic aircraft that is used for training or recreational flying.

The use of lightweight materials in aerobatic aircraft has a number of benefits, including:

- Improved performance: Lightweight materials can help to improve the aircraft’s acceleration, climb rate, top speed, and maneuverability.

- Reduced fuel consumption: Lightweight materials can help to reduce the amount of fuel needed to fly the aircraft, which can extend the aircraft’s range and endurance.

- Increased safety: Lightweight materials can help to improve the aircraft’s safety by making it more resistant to damage in the event of a crash.

The use of lightweight materials is an important part of the design and construction of aerobatic aircraft. By carefully selecting the right lightweight materials, designers can create aircraft that are safe, reliable, and high-performance.

Strengthened Landing Gear:

Strengthened landing gear is important in aerobatic aircraft because it needs to be able to withstand the high stresses imposed during aerobatic maneuvers. Aerobatic aircraft are subjected to a wide range of loads during maneuvers such as hard landings, touch-and-go landings, and aerobatic maneuvers such as loops and rolls. These loads can be significantly higher than those experienced by conventional aircraft.

There are a number of different ways to strengthen the landing gear of an aerobatic aircraft. Some common methods include:

- Using stronger materials: Stronger materials, such as high-strength aluminum alloys and carbon fiber composites, can be used to construct the landing gear. These materials can withstand higher loads without adding significant weight to the aircraft.

- Adding additional structural members: Additional structural members, such as braces and gussets, can be added to the landing gear to increase its strength. These members can help to distribute loads more evenly and prevent the landing gear from failing.

- Redesigning critical components: Critical components of the landing gear, such as the axles and shock struts, can be redesigned to increase their strength and durability. This may involve changing the shape of the components, using thicker materials, or adding additional structural features.

The specific strengthening measures that are required will vary depending on the type of aerobatic aircraft and the maneuvers that it will be used for. For example, an aircraft that will be used for high-performance aerobatics, such as competitive aerobatic competitions, will require more extensive landing gear strengthening measures than an aircraft that will only be used for basic aerobatic maneuvers.

It is important to note that strengthening the landing gear can add weight to the aircraft. This can reduce the aircraft’s performance and payload capacity. It is therefore important to carefully consider the trade-offs between landing gear strength and aircraft weight when designing an aerobatic aircraft.

Here are some examples of strengthened landing gear measures that are commonly used in aerobatic aircraft:

- Axles: The axles are the main load-bearing members of the landing gear. They are typically made of high-strength aluminum alloys or carbon fiber composites. In aerobatic aircraft, axles are often reinforced with additional material or with additional structural members, such as braces and gussets.

- Shock struts: The shock struts absorb the impact of landings and other rough taxiing conditions. In aerobatic aircraft, shock struts are often reinforced with additional material or with additional structural members, such as braces and gussets.

- Wheels and tires: The wheels and tires are also important components of the landing gear. In aerobatic aircraft, wheels and tires are often designed to withstand higher loads and impacts than those used on conventional aircraft.

Strengthened landing gear is an important part of the design and construction of aerobatic aircraft. By carefully considering the loads that the aircraft will be subjected to and by using the appropriate strengthening measures, designers can create an aircraft that is safe and reliable for aerobatic flying.

Aerodynamic Enhancements:

Aerodynamic enhancements are design features that are used to improve the aerodynamic performance of an aircraft. They can be used to reduce drag, increase lift, or improve stability and control. Aerodynamic enhancements are especially important in aerobatic aircraft, which need to be able to perform a wide range of maneuvers without sacrificing performance or safety.

Some common aerodynamic enhancements that are used in aerobatic aircraft include:

- Winglets: Winglets are small vertical surfaces that are attached to the tips of the wings. They help to reduce drag and improve fuel efficiency.

- Vortex generators: Vortex generators are small bumps or ridges that are attached to the surface of the wings. They help to create vortices, which can be used to improve lift and reduce drag.

- Canard wings: Canard wings are small wings that are attached to the front of the aircraft. They can help to improve stability and control, especially at high angles of attack.

- Sweepback: Sweepback is the angle at which the wings are attached to the fuselage. Increasing the sweepback angle can help to reduce drag at high speeds.

- Airfoils: Airfoils are the cross-sectional shape of the wings. There are a variety of different airfoils that can be used, each with its own unique characteristics. Aerobatic aircraft often use airfoils that are designed to provide high lift at a wide range of angles of attack.

The specific aerodynamic enhancements that are used in an aerobatic aircraft will depend on the type of aircraft and the maneuvers that it will be used for. For example, an aircraft that will be used for high-performance aerobatics, such as competitive aerobatic competitions, will require more extensive aerodynamic enhancements than an aircraft that will only be used for basic aerobatic maneuvers.

Aerodynamic enhancements can play a significant role in improving the performance of aerobatic aircraft. By carefully designing and implementing aerodynamic enhancements, designers can create aircraft that are safe, reliable, and high-performance.

Here are some examples of how aerodynamic enhancements can be used to improve the performance of aerobatic aircraft:

- Reduced drag: Aerodynamic enhancements such as winglets and vortex generators can help to reduce drag, which can improve fuel efficiency and increase the aircraft’s range and endurance.

- Increased lift: Aerodynamic enhancements such as canard wings and airfoils that are designed to provide high lift at a wide range of angles of attack can help to improve the aircraft’s lift, which can help to improve its acceleration, climb rate, and maneuverability.

- Improved stability and control: Aerodynamic enhancements such as canard wings and sweepback can help to improve the aircraft’s stability and control, which can make it easier for the pilot to fly the aircraft safely and perform aerobatic maneuvers.

Aerodynamic enhancements are an important part of the design and construction of aerobatic aircraft. By carefully designing and implementing aerodynamic enhancements, designers can create aircraft that are safe, reliable, and high-performance.

Adjustable Control Surfaces:

Adjustable control surfaces are an important feature of aerobatic aircraft. They allow the pilot to fine-tune the aircraft’s handling and performance for different aerobatic maneuvers.

The most common adjustable control surfaces in aerobatic aircraft are:

- Ailerons: Ailerons are located on the trailing edge of the wings and are used to control the aircraft’s roll. Adjustable ailerons allow the pilot to change the amount of aileron deflection, which can be useful for performing certain aerobatic maneuvers, such as rolls and loops.

- Elevator: The elevator is located on the trailing edge of the horizontal stabilizer and is used to control the aircraft’s pitch. Adjustable elevators allow the pilot to change the amount of elevator deflection, which can be useful for performing certain aerobatic maneuvers, such as loops and stalls.

- Rudder: The rudder is located on the trailing edge of the vertical stabilizer and is used to control the aircraft’s yaw. Adjustable rudders allow the pilot to change the amount of rudder deflection, which can be useful for performing certain aerobatic maneuvers, such as spins and turns.

Adjustable control surfaces can be controlled by the pilot using a variety of methods, including:

- Trim tabs: Trim tabs are small movable surfaces that are attached to the trailing edge of the control surfaces. They can be used to fine-tune the aircraft’s trim and handling.

- Adjustable linkages: Adjustable linkages connect the control surfaces to the pilot’s controls. They can be used to change the amount of control surface deflection for different aerobatic maneuvers.

- Electronic control systems: Some aerobatic aircraft use electronic control systems to control the adjustable control surfaces. This allows the pilot to make precise adjustments to the control surfaces using a computer interface.

Adjustable control surfaces are an important tool for aerobatic pilots. They allow the pilot to fine-tune the aircraft’s handling and performance for different aerobatic maneuvers. This can help the pilot to fly the aircraft more safely and perform more precise and challenging maneuvers.

Here are some examples of how adjustable control surfaces can be used to improve the performance of aerobatic aircraft:

- Performing rolls: Adjustable ailerons can be used to increase the amount of aileron deflection, which can help the pilot to perform rolls more quickly and precisely.

- Performing loops: Adjustable elevators can be used to increase the amount of elevator deflection, which can help the pilot to perform loops more smoothly and accurately.

- Performing stalls: Adjustable elevators can be used to increase the amount of elevator deflection, which can help the pilot to break out of stalls more quickly and safely.

- Performing spins: Adjustable rudder can be used to increase the amount of rudder deflection, which can help the pilot to enter and exit spins more easily.

Adjustable control surfaces are a valuable feature of aerobatic aircraft that can help pilots to fly more safely and perform more complex and challenging maneuvers.

Instrumentation:

Instrumentation in aerobatic aircraft is essential for pilots to safely and effectively fly the aircraft and perform aerobatic maneuvers. Aerobatic aircraft are subjected to a wide range of stresses and forces during maneuvers, so it is important for pilots to have accurate and reliable information about the aircraft’s performance and condition.

The most common instruments found in aerobatic aircraft include:

- Altimeter: The altimeter measures the aircraft’s altitude above mean sea level. This is important for pilots to know their altitude during aerobatic maneuvers, as some maneuvers can require the aircraft to fly at very high or low altitudes.

- Airspeed indicator: The airspeed indicator measures the aircraft’s speed relative to the air. This is important for pilots to know their airspeed during aerobatic maneuvers, as some maneuvers require the aircraft to maintain a certain airspeed.

- Attitude indicator: The attitude indicator, also known as the artificial horizon, provides the pilot with a visual representation of the aircraft’s pitch and roll attitude. This is important for pilots to maintain the aircraft’s orientation during aerobatic maneuvers.

- Turn and slip indicator: The turn and slip indicator measures the aircraft’s rate of turn and whether it is slipping or skidding. This is important for pilots to maintain the aircraft’s stability during aerobatic maneuvers.

- Gyrocompass: The gyrocompass provides the pilot with a heading reference that is not affected by the aircraft’s turn rate. This is important for pilots to maintain their desired heading during aerobatic maneuvers.

In addition to these basic instruments, aerobatic aircraft may also be equipped with a variety of other instruments, such as:

- Vertical speed indicator: The vertical speed indicator measures the aircraft’s rate of climb or descent. This is important for pilots to know their vertical speed during aerobatic maneuvers, as some maneuvers can require the aircraft to maintain a certain vertical speed.

- Tachometer: The tachometer measures the speed of the engine. This is important for pilots to monitor the engine’s performance during aerobatic maneuvers, as some maneuvers can put a high load on the engine.

- G-meter: The g-meter measures the amount of g-force that the aircraft is experiencing. This is important for pilots to know the aircraft’s g-force during aerobatic maneuvers, as some maneuvers can subject the aircraft to high g-forces.

- Angle of attack indicator: The angle of attack indicator measures the angle between the aircraft’s longitudinal axis and the relative wind. This is important for pilots to know the aircraft’s angle of attack during aerobatic maneuvers, as some maneuvers can require the aircraft to maintain a certain angle of attack.

The specific instrumentation that is found in an aerobatic aircraft will vary depending on the type of aircraft and the maneuvers that it will be used for. For example, an aircraft that will be used for high-performance aerobatics, such as competitive aerobatic competitions, will require more extensive instrumentation than an aircraft that will only be used for basic aerobatic maneuvers.

Instrumentation is an important part of aerobatic aircraft. By providing pilots with accurate and reliable information about the aircraft’s performance and condition, instrumentation can help pilots to fly more safely and perform more complex and challenging maneuvers.

Weight and Balance Adjustments:

Weight and balance adjustments are essential for safe aerobatic flight. Aerobatic aircraft are subjected to a wide range of loads during maneuvers, so it is important to ensure that the aircraft is properly loaded to maintain its center of gravity (CG) within its safe limits.

The CG is the point at which the aircraft would balance if it were suspended from a string. The CG location affects the aircraft’s stability and handling characteristics. If the CG is too far forward, the aircraft will be nose-heavy and difficult to control. If the CG is too far aft, the aircraft will be tail-heavy and difficult to stall and recover from spins.

Aerobatic aircraft have a narrower CG range than conventional aircraft. This is because aerobatic aircraft are subjected to higher loads and more extreme maneuvers during flight. If the CG is outside of the safe limits, the aircraft may become unstable and difficult to control.

There are a number of ways to adjust the weight and balance of an aerobatic aircraft, including:

- Loading the aircraft: The weight and distribution of the aircraft’s load can have a significant impact on the CG location. Aerobatic pilots must carefully consider the weight and distribution of all passengers, baggage, and fuel when loading the aircraft.

- Using ballast: Ballast is used to add weight to the aircraft to adjust the CG location. Ballast is typically placed in the nose or tail of the aircraft.

- Adjusting the trim: The trim system can be used to adjust the aircraft’s pitch, roll, and yaw attitude. This can also have an impact on the CG location.

It is important to note that weight and balance adjustments can affect the aircraft’s performance. For example, adding ballast will increase the aircraft’s weight, which can reduce its performance.

Aerobatic pilots must be familiar with the weight and balance limitations of their aircraft. They must also be able to perform weight and balance calculations to ensure that the aircraft is properly loaded for each flight.

Here are some tips for weight and balance adjustments in aerobatic aircraft:

- Always use the aircraft’s weight and balance chart. This chart will show you the CG limits for the aircraft and the effect that different loading conditions will have on the CG location.

- Weigh the aircraft before each flight. This will ensure that the aircraft is properly loaded and that the CG is within the safe limits.

- Be aware of the effects of fuel consumption on the CG location. As the aircraft burns fuel, the CG will move aft. This is important to consider when planning aerobatic maneuvers.

- Use ballast to adjust the CG location, if necessary. Be sure to use the correct amount of ballast and to place it in the correct location.

- Adjust the trim to compensate for changes in the CG location. This will help to maintain the aircraft’s desired attitude during flight.

By following these tips, aerobatic pilots can ensure that their aircraft is properly loaded for safe aerobatic flight.

It’s essential to note that building and modifying aerobatic aircraft should be done by experienced aircraft engineers and manufacturers to ensure safety and compliance with aviation regulations. The construction and modification process is highly specialized and requires a deep understanding of aerodynamics and aircraft design.